Lye Safety Guide

What is Lye?

Lye refers to both sodium hydroxide and potassium hydroxide, which are alkali metal hydroxides. Sodium hydroxide lye is more common in modern usage than potassium hydroxide lye. Lye is used in a variety of applications, including as a cleaning product, in soap making, and in food preparation.

Sodium hydroxide has the CAS Number 1310-73-2.

Potassium hydroxide has the CAS Number 1310-58-3.

The CAS Number is used to identify lye, and which type of lye, as an ingredient on safety data sheets (SDS) and other safety documentation. When looking for lye as an ingredient in products, look for one of the above CAS Numbers within the composition table.

Notable Properties of Lye

Lye, both sodium hydroxide and potassium hydroxide, are white, crystalline solids. Lye is commonly available in the form of a powder, flake, or pellet.

What Makes Lye Hazardous?

Lye is a strong base, making it a highly caustic substance. Lower levels of exposure can cause irritation to the skin, eyes, and respiratory system, and higher levels of exposure can lead to severe chemical burns to the skin, eyes, and respiratory system.

According to the National Oceanic and Atmospheric Administration, both sodium hydroxide lye and potassium hydroxide lye release hazardous gases if heated, such as in a fire. They also release the highly flammable gas hydrogen if in contact with both moisture and either zinc or aluminum metal.

What is Lye Water?

Lye water is a solution of sodium hydroxide dissolved in water.

Lye water can be used as a food ingredient. Lye water is a key ingredient in making bagels, pretzels, and ramen noodles.

Lye water can also be used in the process of making soap, with the dissolved lye allowing for easier incorporation into the soap batter.

Since lye water is a liquid, in addition to having the same caustic properties as solid lye, it is capable of splashing and being absorbed into cloth. Being absorbed into cloth can cause prolonged contact, increasing the potential risk and severity of chemical burns.

6 Steps for Safety

Step 1: Read the Warnings

When working with a product for the first time, always read all the safety documents first. This includes safety data sheets, which should be provided by the manufacturer or importer of the lye. There may also be an OSHA chemical label or a Consumer Protection label on the packaging of the lye product. These documents all contain important information on the hazards of the product and instructions on how to mitigate those hazards.

Different compositions in different products may cause additional hazards to be present beyond the properties of plain lye. Be sure to familiarize yourself with the differences between separate lye products.

Step 2: Prepare Your Workspace

Creating a safe workspace, sometimes referred to as engineering control, is a key component of working safely with any potentially hazardous substance. Due to the risk of caustic burns when working with lye, the ability to quickly wash off any lye that contacts the skin or eyes is very important.

Washing out the eyes can be done with an eyewash station. It is possible to purchase an attachment to a skink that will redirect water toward the eyes when opened. It is also possible to purchase sterile saline bottles designed for use as a portable eyewash.

Washing the skin will vary by the amount of contact. For a small area of contact, washing with a sink is sufficient. For a large area of contact, quickly drenching the whole body is necessary. For home settings, a hose or conventional shower should be sufficient. For industrial settings, an emergency deluge shower should be made available in most instances.

Step 3: Gather Your PPE

For Lye, you will need the following PPE.

- Eye Protection

- Safety goggles which create a seal around the eyes are needed to prevent any airborne lye powder from reaching the eyes

- Open safety glasses, which do not have a sealing surface, will not work in preventing dust from reaching the eyes.

- Gloves

- Long, chemical-resistant gloves are needed to prevent skin contact with the hands and forearms.

- Other Body Coverings

- Chemical-Resistant sleeves or an apron may also be necessary to prevent contact with lye.

- Close-Toed shoes with a solid top (not tennis shoes) should be worn if there is a risk of splashing, particularly with lye water.

Step 4: Clear Your Workspace

Having a clear workspace is an important part of safety. Clutter can cause accidents and can prevent you from noticing if something has spilled.

This is also a good time to double-check check any engineering controls, including eye and body washing stations, are working and readily accessible.

If you are working in a shared space, make sure anyone around you can also remain safe when you are working with lye. For those working at home, this can include family members and pets.

Step 5: Do The Work

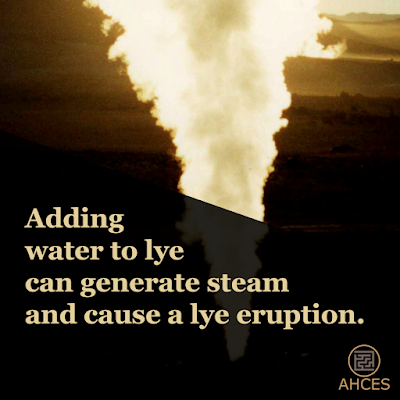

Lye being mixed with water causes an exothermic reaction, heating the solution up. Care should be taken to avoid both chemical and heat burns if mixing lye and water. Be sure to add the lye to water, as adding water to lye causes steam formation, resulting in splashes or in more extreme cases, an eruption of the mixture.

If PPE and good work practices are used properly, working with lye has minimal hazards.

If work cannot be completed in one sitting, be sure to properly seal any lye containers to prevent spills or accidental release when not in use.

Step 6: Clean Up

Use large volumes of water to clean up any spilled lye to dilute the resulting solution. Dilute vinegar, or another dilute acid, may be used to neutralize the lye, but will release heat and carbon dioxide during use.

Be sure to dispose of any waste in accordance with local regulations.

Further Reading

The National Library of Medicine has a PubChem Sodium Hydroxide Entry and Potassium Hydroxide Entry. The National Institute for Occupational Safety and Health (NIOSH) also has Pocket Guides for Sodium Hydroxide and Potassium Hydroxide.

For soap making specific safety, Bramble Berry has an excellent Beginner’s Guide to Lye Safety Video.

Check out the Safety Guide Series Hub for more safety guides.

Sources Cited

National Institute for Occupational Safety and Health (2019, October 30). Sodium hydroxide. Cdc.gov. Retrieved March 29, 2023, from https://www.cdc.gov/niosh/npg/npgd0565.html

Original Posting Date: Mar. 29, 2023

Last Updated: Feb. 14, 2024

Eminent post. I genuinely value examining and moreover esteem your work. This thought is a viable technique for further developing data. Keep on sharing this kind of articles, Thank you.sodium hydroxide formula

ReplyDelete